TheFlashDSM

Supporting Member

- 1,082

- 312

- Feb 18, 2010

-

stony brook,

New_York

I'm going mechanical for my fuel pump, I don't want to spend the money for the fancy Magnus set up, my fuel cell will be in the trunk, what pump do I need, does it come with the coupling?

How to set up the pulley version, I can make my own custom bracket, so I can save the $750, I just would like to get everything I need for the set up.

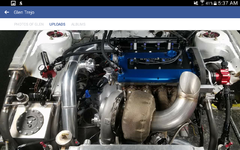

800+ hp build, my build, http://www.dsmtuners.com/threads/my-2g-dsm-second-build-this-ones-going-smoother.499369/

What do I need to do this?

How to set up the pulley version, I can make my own custom bracket, so I can save the $750, I just would like to get everything I need for the set up.

800+ hp build, my build, http://www.dsmtuners.com/threads/my-2g-dsm-second-build-this-ones-going-smoother.499369/

What do I need to do this?

You must be logged in to view this image or video.

You must be logged in to view this image or video.